Introduction

The transition from finishing to shipping creates opportunities to protect quality and speed packing. Use a clean surface protector after the hoop and a reliable pallet wrap before shipment, and you reduce rework while keeping the operation efficient.

This article walks through a practical workflow that pairs water soluble film for embroidery with cast stretch film, and explains the small process changes that deliver better results.

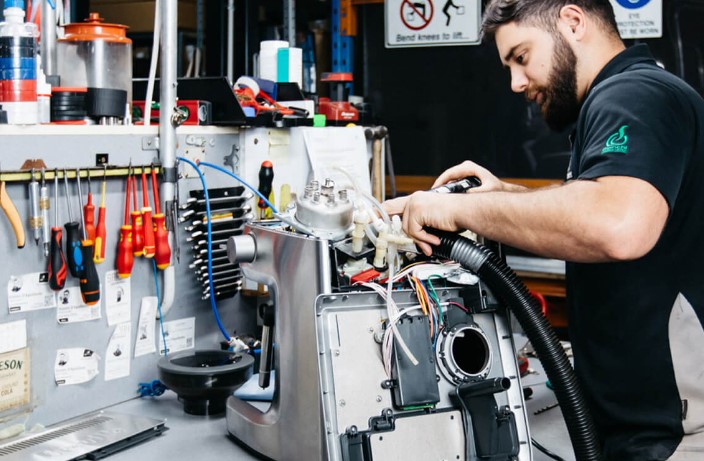

Protect immediately after hoop removal

Right after the hoop, stitches are at their most vulnerable. Placing a single sheet of water soluble film for embroidery over the stitched area supports threads during folding and stacking.

Applying the film at this point reduces manual padding steps and protects the visual and tactile quality of the work.

Folding, boxing, and staging

Fold the garment with the film in place and place it into a polybag or box. Keep the film internal to the package. That prevents external abrasion while the items move through packing.

Stage boxed goods on pallets only after units have cooled and stabilized if your process includes heat tunnels or humid steps.

Secure load with cast stretch film

Once pallets are staged, apply cast stretch film to hold boxes firmly. Cast film’s uniform thickness and predictable machine behavior make it ideal for automatic wrappers and for keeping labelling visible.

It’s the structural layer that ensures your protected goods reach the customer intact.

Operational sequence that works

Finish embroidery and inspect, then apply the water soluble film for embroidery.

Fold or bag the garment, box it, and move the boxes to palletizing.

Wrap the pallet using cast stretch film on your normal wrapper settings.

This keeps the protective film application quick and localized, while the cast film handles transport security.

Testing and quality control

Pilot the flow on a representative batch. Run handling tests and a dissolution check on sacrificial samples. Track damage and packing time to measure benefits.

Storage and environmental controls

Keep soluble films sealed in dry conditions and use them late in the workflow. Cast film needs reasonable storage conditions too; avoid extremes that change pre-stretch behavior.

Conclusion

From hoop to pallet is a clear, repeatable workflow: protect embroidery with water soluble film for embroidery at the finish line and secure the pallet with cast stretch film for transit. Make the small procedural changes and you’ll cut defects, reduce rework, and keep your line moving.