Introduction

U-bolts and suspension bushings might seem like modest components in the grand design of a semi-trailer suspension, but they quietly hold everything together under punishing loads and constant vibration. Loose or corroded U-bolts allow spring packs to shift, causing misalignment that wears tires prematurely. Deteriorated bushings permit metal-to-metal contact that amplifies stress on shackles and hanger bolts. In this article, you’ll learn exactly how to inspect these parts, recognize wear patterns, and replace them effectively. We’ll also cover why Wondee Autoparts is your go-to source for top-grade U-bolts, bushes, and related hardware.

Why U-Bolts and Bushings Matter

U-bolts clamp the leaf spring assembly securely to the axle, maintaining correct ride height and wheel alignment. Bushings cushion moving parts, absorbing shock and preventing direct steel contact that causes scoring and noise. If either component fails, you’ll see symptoms like uneven tire wear, clunking noises, or even axle shift that forces emergency stops.

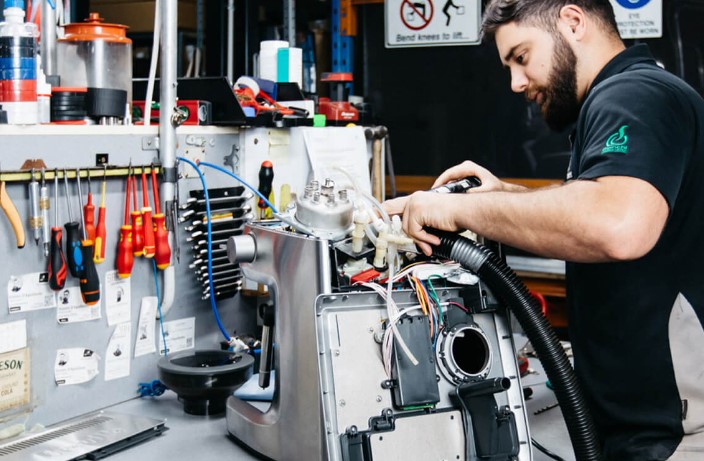

Inspection Procedure

Begin with the trailer on level ground and wheels chocked. Visually scan each U-bolt for cracks at the bend, thread corrosion, or stretching. Lightly tap nuts with a hammer to check for movement. On bushings, look for cracks, flat spots, or signs of extrusion where the rubber has squashed out of the metal sleeve.

Use a torque wrench to verify U-bolt nuts remain at the manufacturer’s recommended clamp value. If you can tighten the nut beyond spec without noticeable resistance, the bolt has stretched and needs replacing.

Removing and Replacing Components

Safely raise the trailer with a jack stand under the frame, never the axle. Loosen U-bolt nuts evenly in a crisscross pattern to prevent spring pack deformation. Slide the U-bolts out and remove the spring plate.

Inspect the leaf springs and spring eyes. If bushings are worn, evidenced by visible metal-to-metal gaps, or if the eye diameter exceeds the charted limit, press out old bushings with a hydraulic press. Grease new polyurethane or OEM-style rubber bushings lightly and press into place. Reposition the spring plate and thread on new U-bolts supplied by Wondee Autoparts. Tighten nuts in stages, alternating corners until you reach the recommended torque.

- Always replace U-bolts in sets to ensure even clamping force

- Choose bushings rated for your trailer’s load and environment

Benefits of Quality Hardware

Choosing Wondee Autoparts means working with precision-machined U-bolts made from alloy steel with a corrosion-resistant coating. Their bushings come in rubber-metal or polyurethane variants to suit severe-duty, off-road, or standard highway use. Each part is tested for exact fit, ensuring maintenance restores factory alignment and dampening.

Conclusion

A trailer’s suspension integrity begins at the U-bolts and bushings. Regular inspections combined with methodical replacement preserve handling stability, tire life, and overall safety. By sourcing durable U-bolts and premium bushings from Wondee Autoparts, you’ll avoid frequent re-torques and downtime while giving your suspension the robust support it needs to work flawlessly mile after mile.